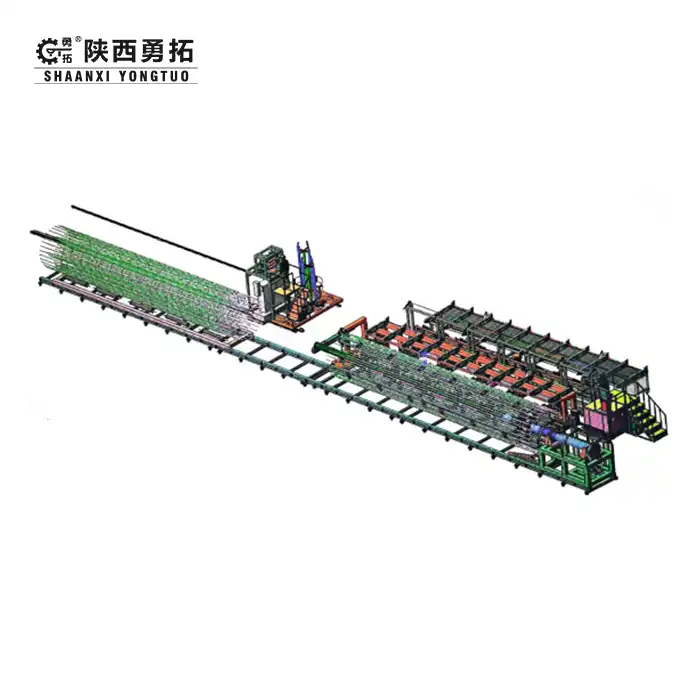

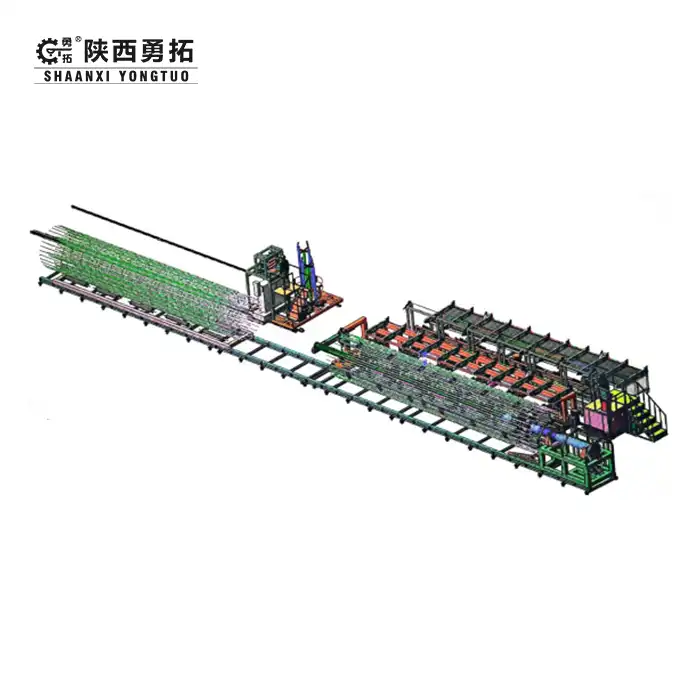

2. Automatic loading, distribution, positioning, indexing and welding of main ribs.

3. There is no need to replace the holding mold when processing 1200-2200mm steel cages, and it is easy to use for odd jobs.

4. The processing of steel cage frame and winding bar processing are carried out at the same time to increase production efficiency."

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner in Automated Construction Solutions

At Shaanxi Yongtuo Machinery Technology Co., Ltd, we specialize in designing and manufacturing Smart Steel Cage Manufacturing Production Lines that redefine efficiency for construction and prefab industries. With 20+ years of expertise, 37 patents, and a focus on automation, our solutions empower builders, manufacturers, and governments to achieve faster, safer, and cost-effective steel cage production.

Why Choose Us?

✅ 20+ Years of R&D Excellence: Backed by a mature engineering team since 2003.

✅ End-to-End Automation: PLC-controlled systems eliminate manual errors and reduce labor costs by 60%.

✅ Global Export Experience: Trusted by clients in 30+ countries for reliable machinery and compliance (ISO, CE).

✅ Rapid After-Sales Support: 24/7 remote diagnostics + on-site service within ≤12 hours (domestic).

✅ Customizable Solutions: Adaptable to steel cage diameters from 1200mm to 2200mm without mold changes.

Features & Advantages

✨ All-in-One Production: Integrated processes for main rib welding, spiral binding, and frame assembly.

✨ Zero Downtime Design: Quick-swap tooling for mixed batches (ideal for odd jobs).

✨ Energy Efficiency: 30% lower power consumption vs. traditional lines.

✨ IoT-Ready: Real-time monitoring via touchscreen HMI for predictive maintenance.

✨ Future-Proof: Compatible with MES/ERP systems for Industry 4.0 integration.

Technical Parameters

|

Applications

Our automated steel cage welding system is ideal for:

- Bridge & Tunnel Projects: High-speed rail, subsea tunnels.

- Prefab Concrete Factories: Reinforced columns, piles, beams.

- Municipal Engineering: Water pipelines, urban rail transit.

- High-Rise Buildings: Core tube reinforcement cages.

Customization Options

Tailor your production line with:

- Multi-Size Compatibility: Adjustable molds for non-standard diameters.

- Branded Control Interfaces: Add your company's logo/software.

- Localized Training: On-site operator & maintenance workshops.

Certifications

🔹 ISO 9001:2015 Quality Management

🔹 CE Certification (EN 1090)

🔹 37 Valid Patents in Automation & Welding

After-Sales Service

We guarantee:

- 24/7 Remote Troubleshooting: Connect via email/phone for instant support.

- Spare Parts Inventory: 95% components available for same-day shipping.

- Lifetime Upgrades: Software updates for evolving needs.

Packaging & Shipping

- Waterproof wooden crates with shock-absorbent foam.

- FOB/CIF terms available for global clients.

About Shaanxi Yongtuo

Established in 2003, we have firmly established ourselves as a leading innovator in CNC machinery. Our 50,000㎡ factory in Xi'an serves as a powerhouse of advanced manufacturing, equipped with state - of - the - art facilities. Our flagship Smart Steel Cage Manufacturing Production Line has gained wide acclaim. It has been successfully deployed in globally significant landmark projects such as the Jakarta - Bandung High - Speed Railway in Indonesia, where it has contributed to the creation of a modern and efficient transportation network. In Dubai, it has played a crucial role in the Dubai Metro Extension, helping to expand the city's world - class metro infrastructure. These deployments highlight our commitment to delivering high - quality, innovative solutions for large - scale construction initiatives around the world.

Factory Tour & Exhibitions

Whether you're visiting our 50,000㎡ smart manufacturing base in Xi’an or meeting us at an international exhibition, we’re excited to show you how our Intelligent Steel Cage Forming Production Lines are transforming infrastructure and energy projects worldwide.

FAQ

Q1: Can this line handle twisted steel bars?

A: Yes, our indexing system ensures precise alignment for deformed rebars.

Q2: What's the ROI timeline?

A: Clients typically recover costs in 2–3 years via labor savings.

Q3: Do you offer financing options?

A: Yes, partnerships with CNCB Leasing for flexible payment plans.

Q4: How long is the warranty?

A: 2 years for core components, extendable to 5 years.

Q5: Can you retrofit older equipment?

A: Yes! We upgrade legacy systems with PLC controls.

Contact Us Today!

📧 Email: sxyongtuo@gmail.com

Upgrade to Yongtuo's Smart Steel Cage Manufacturing Production Line – Precision Engineered for Your Success!

YOU MAY LIKE

_1744680888628.png)