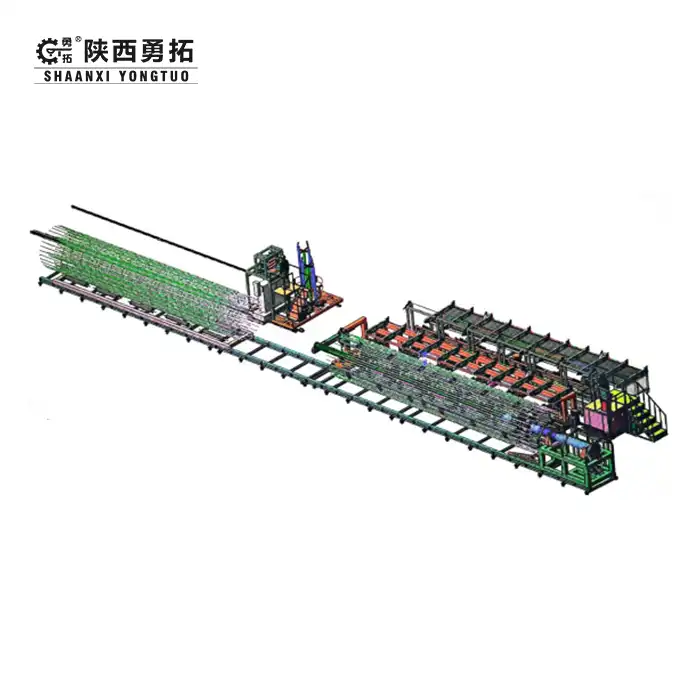

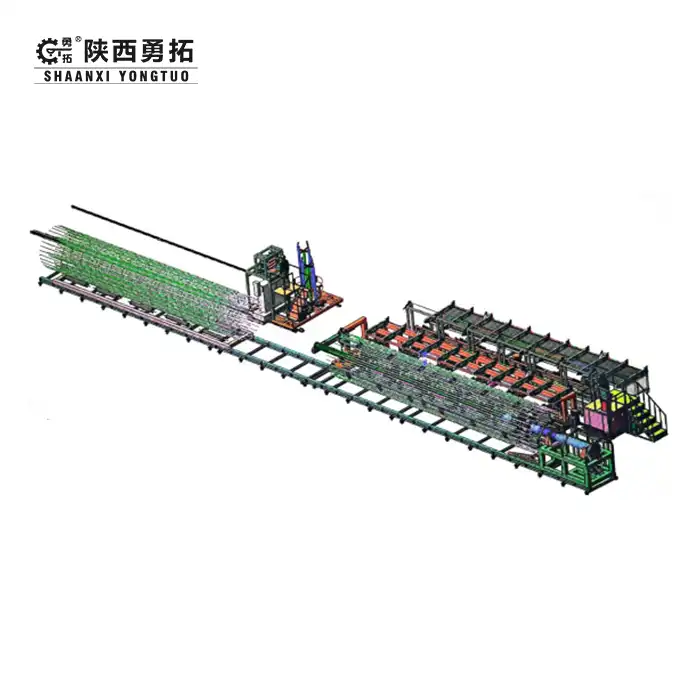

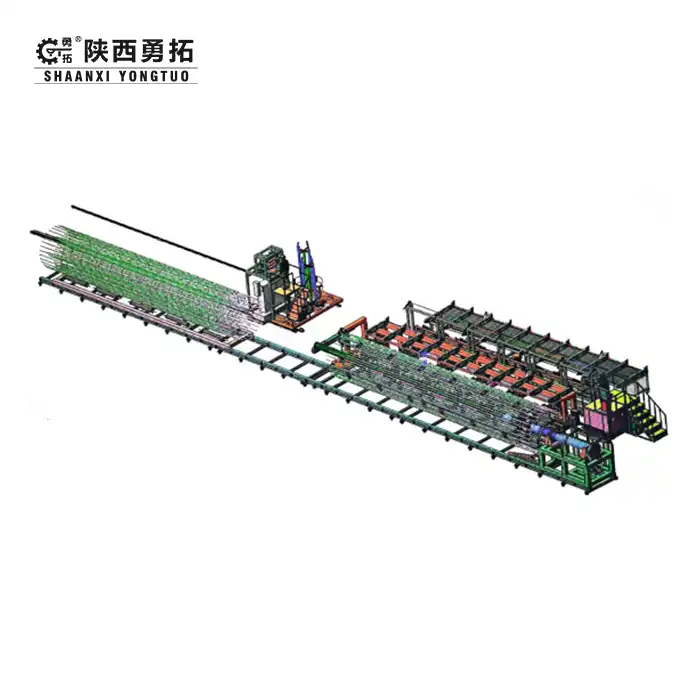

2. Automatic loading, distribution, positioning, indexing and welding of main ribs.

3. There is no need to replace the holding mold when processing 1200-2200mm steel cages, and it is easy to use for odd jobs.

4. The processing of steel cage frame and winding bar processing are carried out at the same time to increase production efficiency."

Why Trust Shaanxi Yongtuo Machinery Technology Co., Ltd?

Shaanxi Yongtuo Machinery Technology Co., Ltd is a leading Intelligent Steel Cage Forming Production Line manufacturer and supplier with 20+ years of expertise. Our solutions combine advanced PLC automation, energy-efficient designs, and ISO-certified quality to help construction and energy industries produce high-precision steel cages faster.

Why Choose Us?

✅ 20+ Years of Expertise: Trusted by global clients like China Railway and overseas infrastructure projects.

✅ 37 Valid Patents: Core technologies ensure unmatched precision (≤2mm error) and durability.

✅ 24/7 Support: On-site maintenance within 12 hours (domestic) and multilingual remote assistance.

✅ Cost Savings: Reduce labor costs by 60% and material waste by 25% with automated workflows.

Features & Advantages

🔧 Fully Automated Production: PLC-controlled system integrates loading, welding, and forming.

🔧 Zero Mold Replacement: Process 1200-2200mm cages without changing molds.

🔧 Dual-Task Efficiency: Simultaneously handle cage frames and winding bars for 30% faster output.

🔧 IoT-Ready: Remote monitoring and predictive maintenance via smart sensors.

Technical Parameters

|

Applications

🌉 Infrastructure: Bridges, tunnels, highways.

⚡ Energy Projects: Wind turbine foundations, nuclear reactor reinforcements.

🏗️ Prefabrication: Precast concrete plants and modular construction.

Customization Options

Tailor your Intelligent Steel Cage Forming Production Line for:

- Climate Adaptations: Anti-corrosion coatings for coastal/offshore projects.

- Language Interfaces: English, Arabic, or multilingual HMIs.

- ERP Integration: Sync production data with your management systems.

Certifications

✔️ ISO 9001 ✔️ CE ✔️ SGS

After-Sales Service

- Free Training: 3-day onsite operator training.

- Warranty: 2-year coverage + lifetime technical support.

- Global Spare Parts Network: 48-hour delivery guarantee.

Packaging & Shipping

Our waterproof wooden crates are designed to offer top - notch protection for your valuable cargo during transit. Constructed from high - quality, treated wood, they are impervious to moisture, safeguarding your items from rain, humidity, and any water - related risks. What's more, we've integrated GPS - tracked logistics into our shipping process. With this advanced technology, you can monitor the real - time location of your shipment at any given moment. Whether it's on a truck, a ship, or in transit between warehouses, you'll have complete visibility, ensuring peace of mind throughout the entire shipping journey. This combination of secure packaging and cutting - edge tracking makes our shipping services reliable and convenient for all your transportation needs.

About Shaanxi Yongtuo

Established in 2003, we have been a leading provider in the steel cage forming solutions domain. Over the years, we've successfully delivered 500+ such solutions to 30+ countries around the world. Our sprawling 50,000㎡ factory is a technological marvel, equipped with state - of - the - art CNC machining centers that ensure precision in every component. The robotic assembly lines further enhance our production efficiency, allowing us to meet high - volume demands without compromising on quality.

Customer Visits & Exhibitions

At Shaanxi Yongtuo Machinery Technology Co., Ltd., we believe in building trust through face-to-face communication and hands-on demonstrations. Over the years, we have actively participated in major international exhibitions and welcomed hundreds of global clients to our facility for factory tours, technical discussions, and on-site equipment trials.

FAQ

Q: Can this line handle irregular cage shapes?

A: Yes! Our adaptive welding heads adjust to non-standard designs.

Q: What's the ROI period?

A: Most clients recover costs in 8-12 months via labor/material savings.

Q: Is installation included?

A: Free global installation by our engineers.

Q: Do you provide CAD drawings?

A: Yes – share your specs, and we'll design a 3D model.

Q: How to handle power fluctuations?

A: Built-in voltage stabilizers ensure consistent performance.

Contact Us Today!

📧 Email: sxyongtuo@gmail.com

We look forward to working with forward-thinking partners around the world to promote innovation in the field of Intelligent Steel Cage Forming Production Line.

YOU MAY LIKE

_1744680888628.png)