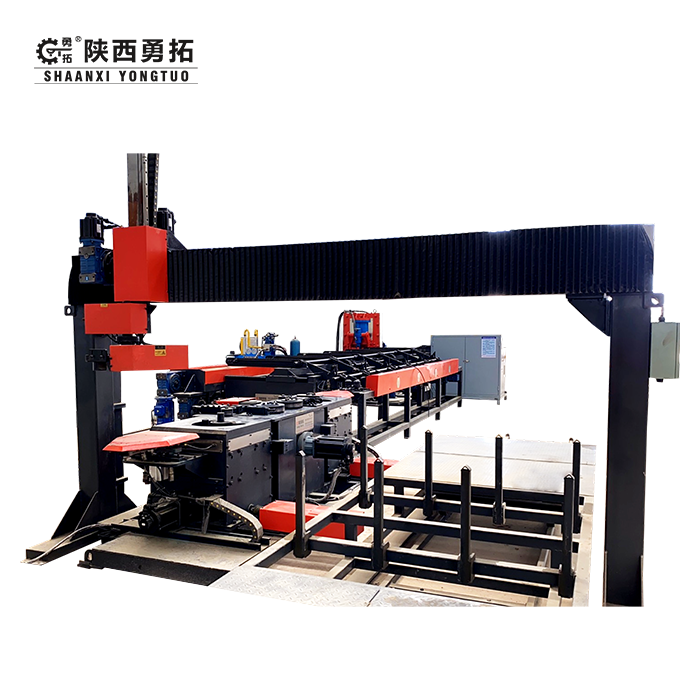

2.200-ton hydraulic shearing head,high shearing and blanking efficiency.

3.Equipped with automatic tail collection device to reduce work intensity.

4.The collection of finished products is carried out by robots, and the finished products are automatically collected and processed.

5. Large platform-type collecting truck can collect more finished products.

6.A variety of graphic process parameters can be stored in the library, which is convenient and quick to call at anytime.

7. An optional ladder automatic feeding device can be installed to realize automatic feeding of raw materials."

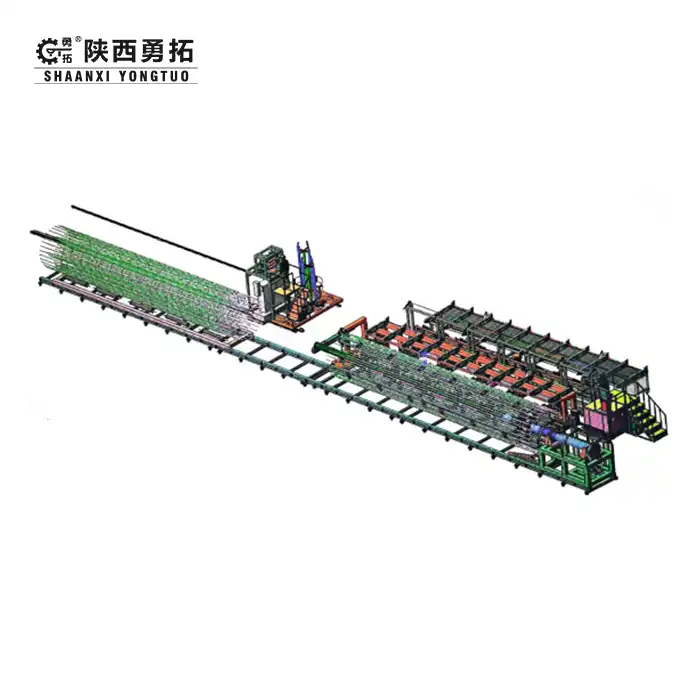

Discover the Future of Steel Processing: Intelligent Cutting Bending And Hooking Production Line by Shaanxi Yongtuo

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Cutting Bending And Hooking Production Line manufacturer and supplier. With 37 patents, a mature R&D team, and 20+ years of export expertise, we deliver advanced, energy-saving, and reliable automation solutions for steel bar processing.

Why Choose Us?

✅ 20+ Years of Expertise: Trusted by global clients in construction, automotive, and aerospace sectors.

✅ 1-on-1 Customization: Tailor-made solutions for material types, output capacity, and factory layouts.

✅ 24/7 After-Sales Support: ≤12-hourFailureResponse, 1-year warranty, and free remote troubleshooting.

✅ Energy-Saving Design: 30% lower Energy consumption vs. Traditional equipment.

✅ Certified Quality: ISO 9001, CE, and TUV EduTrust Certification Scheme

Features & Advantages

-

200-Ton Hydraulic Shearing: Cuts steel bars (≤50mm) in seconds.

-

Robot-Aided Collection: ±0.1mm precision with 6-axis robotic arms.

-

Automatic Feeding: Ladder feeder reduces manual loading by 90%.

-

Cloud Storage: Stores 100+ shape parameters for quick recall.

-

Large Platform Truck: Collects 500+ finished parts per batch.

Technical Parameters

Applications

Ideal for steel bars, rebar, and metal pipes in:

Construction: Precast beams, tunnel reinforcements.

Automotive: Chassis, exhaust systems.

Energy: Wind turbine towers, solar holder.

Furniture: Decorative metal frames.

Customization Options

Material Adaptation: Adjust rollers for stainless steel, aluminum, or copper.

Software Upgrades: Add AI Optimal Layout Ant Algorith

to optimize material usage by 15%.

Safety Kits: Laser guards, emergency stop systems.

Certifications

Our Intelligent Cutting Bending And Hooking Production Line is a paragon of quality and compliance, boasting ISO 9001, CE, and TUV certifications. The ISO 9001 certification attests to our commitment to maintaining a high - quality management system, ensuring consistent product excellence. The CE mark indicates that our products meet the essential health, safety, and environmental protection requirements set by the EU. Meanwhile, the TUV certification, renowned for its rigorous testing, further validates our products' compliance with EU safety and performance standards. This comprehensive suite of certifications assures our customers, both within the EU and globally, of the reliability and top - notch quality of our offerings.

After-Sales Service

24/7 Remote Support: Diagnose issues via IoT sensors.

Global Spare Parts Network: 3-day delivery for 98% of components.

Onsite Training: Teach operators in 5 days.

Packaging & Shipping

Waterproof wooden crates with shock-absorbent foam.

FOB/CIF terms to 50+ countries.

About Shaanxi Yongtuo

Founded in 2003, we've emerged as a prominent high - tech enterprise. Our 20,000㎡ factory in Xi'an serves as a bustling center of innovation and production. With a team of over 120 dedicated engineers, we've been at the forefront of technological advancements. Their expertise has enabled us to deploy more than 3,000 machines across 30 countries. These machines, ranging from advanced manufacturing equipment to intelligent industrial systems, have not only met but exceeded the expectations of clients worldwide, solidifying our position in the global market.

FAQ

Q: Can this line handle irregular-shaped materials?

A: Yes! Our modular rollers adapt to oval, square, or hexagonal bars.

Q: What's the ROI period?

A: Most clients recover costs in 14-18 months via labor savings.

Q: Do you provide installation videos?

A: Yes! Access multilingual guides on our YouTube channel.

Q: How to handle material jams?

A: The self-diagnosis system auto-reverses rollers in 2 seconds.

Q: Can I visit your factory?

A: Absolutely! Schedule a tour via 13892319900@sxyongtuo.com.

Join 500+ Satisfied Clients Today! 📞

📩 Email: sxyongtuo@gmail.com

Upgrade to Shaanxi Yongtuo's Intelligent Cutting Bending And Hooking Production Line – where innovation meets reliability. Request a quote now!

YOU MAY LIKE

_1744680888628.png)