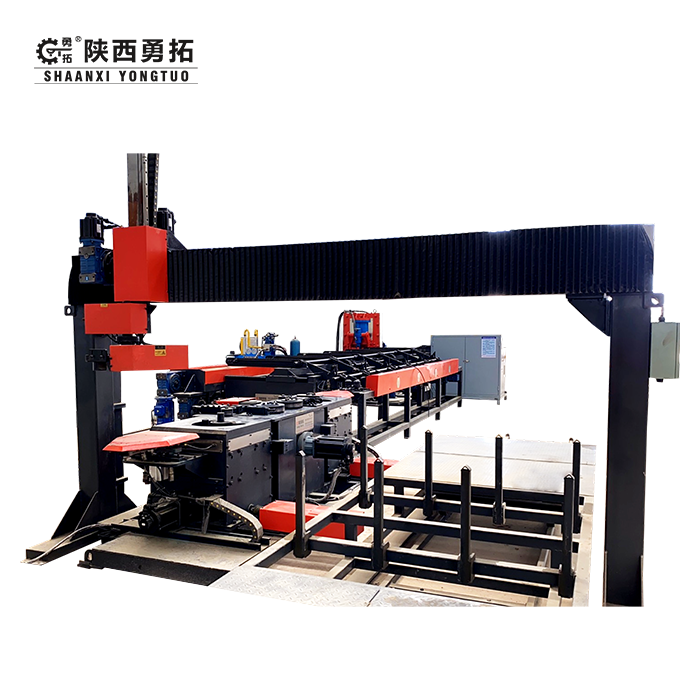

2.200-ton hydraulic shearing head,high shearing and blanking efficiency.

3.Equipped with automatic tail collection device to reduce work intensity.

4.The collection of finished products is carried out by robots, and the finished products are automatically collected and processed.

5. Large platform-type collecting truck can collect more finished products.

6.A variety of graphic process parameters can be stored in the library, which is convenient and quick to call at anytime.

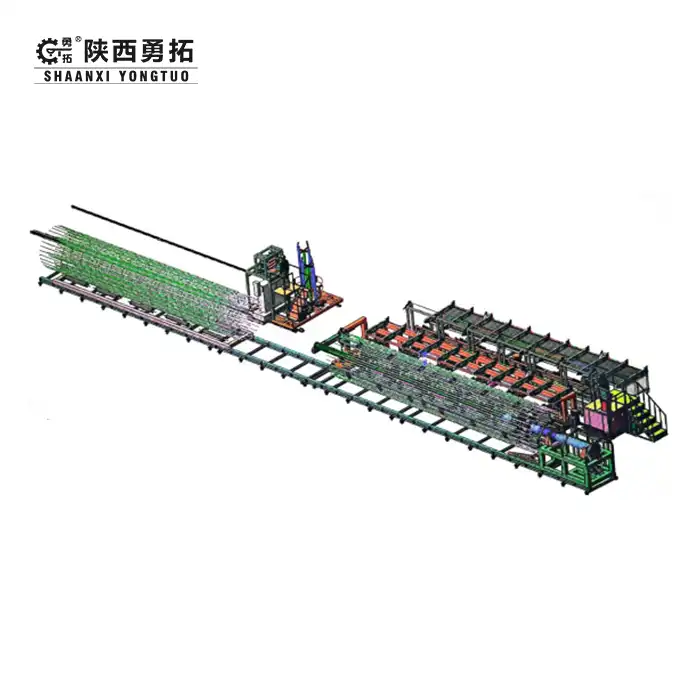

7. An optional ladder automatic feeding device can be installed to realize automatic feeding of raw materials."

Smart Cutting Bending and Hooking Manufacturing Line – Your Ultimate Automation Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Smart Cutting Bending and Hooking Manufacturing Line manufacturer. With 37 patents, a mature R&D team, and 24/7 global support, we deliver advanced, energy-saving, and reliable steel bar processing solutions.

Why Choose Us?

- ✅ 20+ Years Expertise: Trusted by 1,200+ clients globally.

- ✅ Full Automation: Integrates feeding, cutting, bending, and hooking seamlessly.

- ✅ Custom Solutions: Adapt to diverse material specifications.

- ✅ Energy Efficiency: 30% lower energy consumption vs. competitors.

- ✅ Rapid Service: ≤12-hour fault response, 24/7 remote diagnostics.

Features & Advantages

- ⚙️ 200-Ton Hydraulic Shearing: High-speed cutting for bulk processing.

- ⚙️ Robotic Collection: Minimizes manual labor with automated stacking.

- ⚙️ Large Platform Truck: Stores 2x more finished products.

- ⚙️ Pre-Programmed Parameters: Save 20+ bending patterns for instant recall.

- ⚙️ IoT-Ready Design: Optional real-time monitoring for Industry 4.0 integration.

Product Parameters

|

Product Details

Our Smart Cutting Bending and Hooking Manufacturing Line features a PLC control system, servo-driven bending heads, and a touchscreen interface. The modular design allows easy upgrades, while the anti-collision sensors ensure operator safety.

Application Areas

- 🏗️ Construction (rebar bending)

- 🔧 Automotive (chassis parts)

- 🏭 Metal Fabrication (structural components)

- 🛋️ Furniture (metal frames)

- ✈️ Aerospace (high-precision brackets)

Customization Options

- Ladder Feeding Add-On: Automate raw material loading.

- Multi-Language Interface: English, Spanish, Arabic, etc.

- CE/ISO Certification Prep: Compliance for European markets.

Certification

ISO 9001, CE, and SGS certified. Compliant with OSHA safety standards.

After-Sales Service

- 2-Year Warranty: Free spare parts for manufacturing defects.

- Onsite Training: 3-day operator and technician workshops.

Packaging

Waterproof wooden crates with foam cushioning. Export-ready labeling.

Company Introduction

Based in Xi'an, China, Yongtuo has been a leading name in the field of CNC bending machinery since 2003. Our expansive 50,000㎡ factory is a hive of activity, housing advanced manufacturing equipment and a highly skilled workforce. This facility allows us to produce top - notch CNC bending machines with precision and efficiency. Over the years, we have built a strong reputation, serving clients in 30+ countries. Our commitment to innovation and quality has made us the go - to choice for businesses worldwide, seeking reliable and high - performance bending solutions for their manufacturing needs.

Our Factory

Our state - of - the - art facility is equipped with cutting - edge CNC laser cutters that ensure precision cuts down to the smallest detail, enabling the creation of intricate components. The robotic welders, programmed with advanced algorithms, provide consistent and high - quality welds, significantly enhancing the durability of our products. Complementing these are our 500 - meter testing lines, where each unit undergoes rigorous performance evaluations. With this setup, our annual capacity stands at an impressive 200+ units. This capacity, combined with our top - tier equipment, allows us to meet the high - volume demands of our clients while maintaining the highest standards of quality.

Customer Visit

We warmly welcome customers from around the world to visit our factory. Through on-site inspections, technical exchanges, and face-to-face communication, clients gain a clear understanding of our manufacturing capabilities, quality control processes, and commitment to long-term partnerships. These visits not only build trust but also lay the foundation for deeper cooperation and customized solutions.

Exhibitions

We actively participate in global industry exhibitions, showcasing our latest innovations and cutting-edge technology. These events provide an excellent platform for direct engagement with potential clients, exchanging industry insights, and strengthening relationships with both existing and new partners.

FAQ

Q: Can this Smart Cutting Bending and Hooking Manufacturing Line handle stainless steel?

A: Yes! It processes carbon steel, stainless steel, and alloy rods (up to HRB 400).

Q: What's the ROI timeline?

A: Typically 12–18 months via labor cost savings.

Q: Do you provide installation support?

A: Free remote guidance; onsite engineers available (fee applies).

Q: How to update bending parameters?

A: Use the USB port or cloud-based software (optional).

Q: Payment terms?

A: 30% deposit, 70% before shipment. LC accepted.

Contact Us

📧 Email: sxyongtuo@gmail.com

Upgrade your production with the Smart Cutting Bending and Hooking Manufacturing Line – precision engineered for your success!

YOU MAY LIKE

_1744680888628.png)