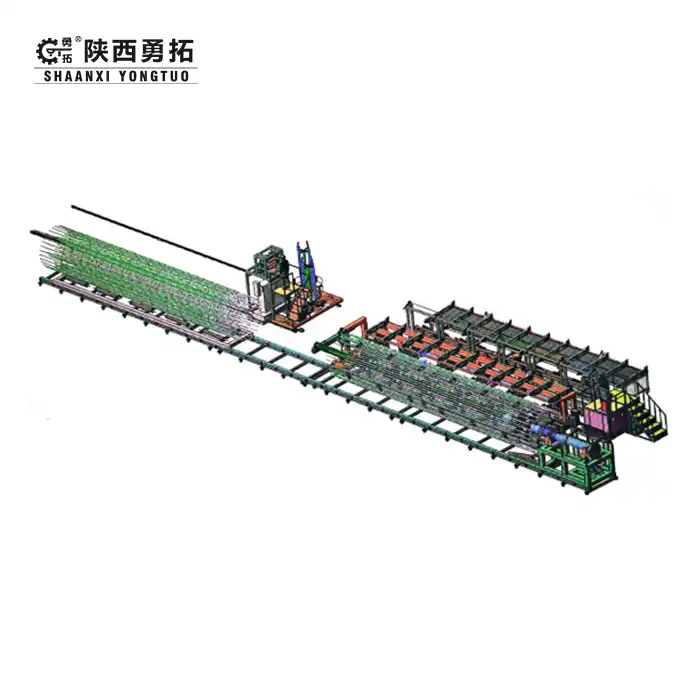

2. Automatic loading, distribution, positioning, indexing and welding of main ribs.

3. There is no need to replace the holding mold when processing 1200-2200mm steel cages, and it is easy to use for odd jobs.

4. The processing of steel cage frame and winding bar processing are carried out at the same time to increase production efficiency."

Shaanxi Yongtuo: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing Intelligent Steel Cage Construction Production Systems with 37 patents and 20+ years of R&D expertise. Our systems deliver advanced automation, energy efficiency, and unmatched reliability for global construction projects.

Why Choose Us?

✅ Advanced Technology: PLC-integrated control ensures 85%+ automation.

✅ Energy-Saving Design: 20% lower power consumption vs. traditional systems.

✅ Proven Performance: 99% uptime with ISO 9001-certified manufacturing.

✅ Global Support: 24/7 multilingual service, ≤12-hour fault response.

✅ Cost Efficiency: Reduce labor costs by 40% and material waste by 15%.

Features & Advantages

- Fully Automated Assembly Line: PLC-controlled workflow for seamless production.

- Zero Mold Replacement: Process 1200–2200mm cages without tool changes.

- Dual-Task Processing: Simultaneously weld frames and winding bars, boosting output by 30%.

- Smart Error Detection: Laser-guided alignment (±1mm accuracy).

- Cloud Connectivity: Remote monitoring via IoT-enabled dashboards.

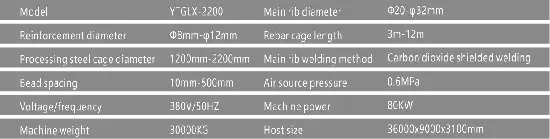

Product Parameters

Product Detailed Demo

Our Intelligent Steel Cage Construction Production System features a modular design with:

- Automatic Loading Module: RFID-tagged material sorting.

- Multi-Axis Welding Arm: 360° rotation for complex geometries.

- BIM Integration: Import 3D models for custom cage designs.

Application Areas

- Bridges & Tunnels: High-speed rail, underwater tunnels.

- Energy Projects: Wind turbine foundations, nuclear containment.

- Urban Infrastructure: Skyscrapers, subway stations.

Customization Options

- BIM/Revit Compatibility: Seamless data import for bespoke designs.

- Modular Expansion: Add units for multi-project parallel processing.

- Voltage Adaptation: 220V–480V configurations for global use.

Certifications

- ISO 9001, CE, GB 50661 welding standards.

- TÜV-certified safety protocols.

After-Sales Service

- 24/7 remote diagnostics.

- On-site maintenance within 48 hours (globally).

- Free operator training (10+ languages).

Packaging

- Waterproof, shockproof crates with GPS tracking.

- Customizable for sea/air freight.

Company Introduction

With 20+ years in steel processing machinery, Shaanxi Yongtuo has supplied systems to 50+ countries, including projects like the Hong Kong-Zhuhai-Macao Bridge.

Our Factory

- 32,000m² production base in Xi'an.

- Robotic welding lines with 0.01mm precision.

Customer Visits

In 2023, our facility witnessed an influx of over 500 global clients, a testament to our growing reputation in the industry. These inspections were not just routine visits; they were in - depth evaluations of our manufacturing processes, quality control measures, and technological capabilities.

Exhibitions

Engage in live product demonstrations, and gain exclusive insights into our innovative technologies that are revolutionizing the construction landscape. Similarly, at the ASEAN Construction Expo, we'll be highlighting our products tailored to the unique needs of the Southeast Asian market. Don't miss these prime opportunities to network, explore new business prospects, and witness firsthand how our offerings can enhance your construction projects' efficiency and success.

FAQs

Q: What's the ROI timeframe?

A: Typical ROI in 18–24 months via labor/material savings.

Q: Do you provide on-site training?

A: Yes – 5-day training included with purchase.

Q: Can it handle curved cages?

A: Yes – our 6-axis welder supports 3D contours.

Q: Lead time for delivery?

A: 60–90 days after deposit.

Q: Warranty coverage?

A: 2-year warranty on critical components.

Contact Us

Ready to upgrade your Intelligent Steel Cage Construction Production System?

📧 sxyongtuo@gmail.com

Your success is our mission—visit us or connect anytime to explore how we can support your next project.

YOU MAY LIKE

_1744680888628.png)