1. Multi-station raw material storage bin, which can store raw materials of different specifications.

2. Reinforced frame design, which can process 40mm rebar for a long time.

3. Automatic magnetic gantry loading, which can solve the problem of automatic loading of steel bar raw materials.

4. 250-ton shearing cylinder, high production efficiency.

5. 40mm thick blade has high strength and long service life.

6. Servo control cut-to-length, high cutting accuracy and good consistency.

7. Equipped with tail material collection box, centralized collection of tail materials.

8. Three-station finished product collection bin meets the centralized collection of various specifications.

9. The collection bin is equipped with a collection steel chain to reduce collection noise.

10. Feeding, cutting, shearing, bending and collection are completed in one machine, realizing automatic processing of the whole process.

11. The bending speed can be set arbitrarily, with higher processing flexibility.

12. Equipped with three sets of three-axis manipulators to perform bending loading.

13. Equipped with three sets of three-axis manipulators to perform finished product collection.

14. Bending loading and finished product collection are performed separately to improve production efficiency.

15. The multi-station finished product collection bin can collect finished products of various specifications at the same time.

16. The bending adopts a planetary reducer as the torque transmission, which has low noise, high precision and long service life.

17. The middle clamping adopts multi-piece flexible clamping, which can solve the effective clamping of multiple steel bars and ensure the consistency of the processing size of multiple teel bars.

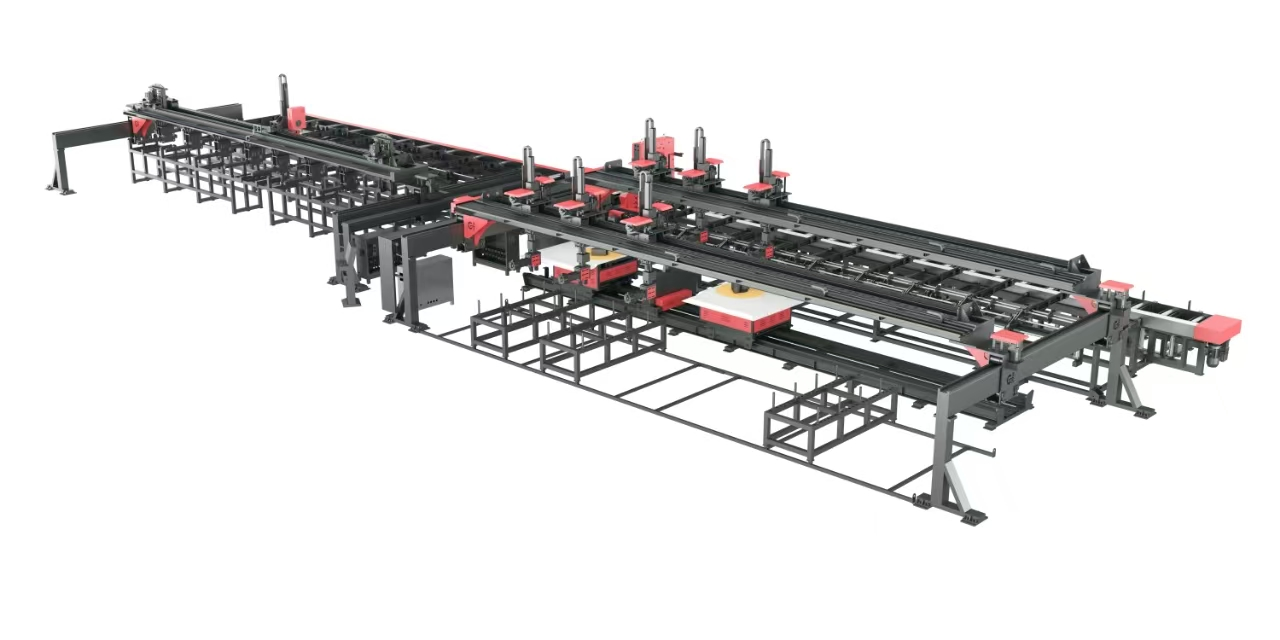

Ⅰ、YTJHW2P-40 double-gutter shearing and bending production line

Rebar processing category: bar steel bars

Processing category: automatic loading, cut to length, automatic bending, automatic stacking

1.1 Double-gutter shearing and bending production line diagram

1.2 Dimensions of double frame shearing and bending production line

1.3Equipment component details

Ⅱ、Equipment parameters

Processing graphics sample

|

Model |

YTJHW2P-40 |

Processing range |

Φ16mm-Φ40mm |

||||||

|

Shear force |

2500KN |

Cutting length range |

1200mm-12000mm |

||||||

|

Blade width |

600mm |

Conveying speed |

1000mm/s |

||||||

|

Cutting parameters |

Steel bar diameter |

Φ16 |

Φ20 |

Φ25 |

Φ28 |

Φ32 |

Φ36 |

Φ40 |

|

|

Single cutting number |

30 |

24 |

20 |

18 |

15 |

13 |

10 |

||

|

Bending workpiece extended length |

2000-12000mm |

The shortest length of the middle section of the curved figure |

1800mm |

||||||

|

Bending parameters |

Steel bar diameter |

Φ16 |

Φ20 |

Φ25 |

Φ28 |

Φ32 |

Φ36 |

Φ40 |

|

|

Single bending number |

4 |

4 |

3 |

2 |

2 |

1 |

1 |

||

|

Machine power |

about=150KW |

Air source pressure |

0.6MPa |

||||||

|

Machine weight |

about=40T |

Dimensions |

about=40000x10000x3400mm |

||||||

Ⅲ、Shearing capacity (taking 6m cutting length as an example)

|

Number |

Steel bar diameter |

Single cutting number |

Hourly production capacity |

10 hours of production capacity |

Remark |

|

1. |

Φ12 |

35 roots |

10000KG |

100t |

|

|

2. |

Φ16 |

30 roots |

16000KG |

160t |

|

|

3. |

Φ20 |

24 roots |

22000KG |

220t |

|

|

4. |

Φ25 |

20 roots |

28000KG |

280t |

|

|

5. |

Φ28 |

18 roots |

32000KG |

320t |

|

|

6. |

Φ32 |

15 roots |

35000KG |

350t |

|

|

7. |

Φ36 |

13 roots |

38000KG |

380t |

|

|

8. |

Φ40 |

10 roots |

36000KG |

360t |

|

Bending production capacity (taking 6-meter-long hook-shaped figure at both ends as an example)

|

Number |

Steel bar diameter |

Single cutting number |

Hourly production capacity |

10 hours of production capacity |

Remark |

|

1. |

Φ16 |

4 roots |

4500KG |

45t |

|

|

2. |

Φ20 |

4 roots |

7000KG |

70t |

|

|

3. |

Φ25 |

3 roots |

8000KG |

80t |

|

|

4. |

Φ28 |

2 roots |

7000KG |

70t |

|

|

5. |

Φ32 |

1 roots |

4300KG |

43t |

|

|

6. |

Φ36 |

1 roots |

5700KG |

57t |

|

|

7. |

Φ40 |

1 roots |

7200KG |

72t |

|

Ⅳ、Production line advantages

1. Multi-station raw material storage bin, which can store raw materials of different specifications.

2. Reinforced frame design, which can process 40mm rebar for a long time.

3. Automatic magnetic gantry loading, which can solve the problem of automatic loading of steel bar raw materials.

4. 250-ton shearing cylinder, high production efficiency.

5. 40mm thick blade has high strength and long service life.

6. Servo control cut-to-length, high cutting accuracy and good consistency.

7. Equipped with tail material collection box, centralized collection of tail materials.

8. Three-station finished product collection bin meets the centralized collection of various specifications.

9. The collection bin is equipped with a collection steel chain to reduce collection noise.

10. Feeding, cutting, shearing, bending and collection are completed in one machine, realizing automatic processing of the whole process.

11. The bending speed can be set arbitrarily, with higher processing flexibility.

12. Equipped with three sets of three-axis manipulators to perform bending loading.

13. Equipped with three sets of three-axis manipulators to perform finished product collection.

14. Bending loading and finished product collection are performed separately to improve production efficiency.

15. The multi-station finished product collection bin can collect finished products of various specifications at the same time.

16. The bending adopts a planetary reducer as the torque transmission, which has low noise, high precision and long service life.

17. The middle clamping adopts multi-piece flexible clamping, which can solve the effective clamping of multiple steel bars and ensure the consistency of the processing size of multiple teel bars.

Ⅴ、Details

1. The feeding trough is 600mm wide and can feed multiple steel bars for processing

2. The feeding roller is quenched and has a long service life

3. Length setting: Servo motor is used to drive the length setting, and the length setting accuracy can reach ±1mm

4.Shear head: 2500KN hydraulic shear, heavy-duty frame design, strong rigidity, stable operation and 24-hour uninterrupted work.

5.Tailings collection: A tailings collection device is designed to collect the remaining tailings after shearing. No need to pick them up manually, which is convenient and safe.

6.Cutting and unloading: Double-sided six-station material collection bin, which can collect finished steel bars of various specifications

7. Magnetic feeding system reduces the labor of workers

8. Double rack system takes the raw material and automatically bends it

9. The double rack system automatically takes finished products and places them for palletizing

Ⅵ、 Standard configuration list of YTJH2P-40

|

Number |

Denomination |

Specification |

Quantity |

Remark |

|

1 |

Host |

YTJHW2P-40 |

1 set |

|

|

2 |

Air Compressor |

Equipment supporting special |

1 set |

7.5KW |

|

3 |

Random accessories, tools and operating manual |

Equipment supporting special |

1 set |

|

YOU MAY LIKE

_1744680888628.png)