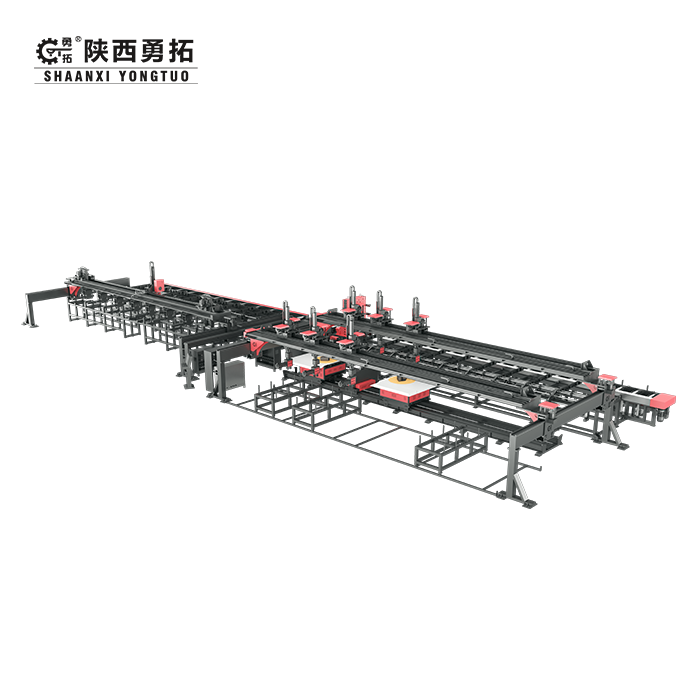

一、Fully Automatic Bar Shearing And Bending Workstation/YTJHW2P-40

The equipment is designed for the shearing and bending of bars. It can realize the whole process automation of raw material loading, automatic counting, conveying, cut-to-length, bending and collection, so as to reduce production costs and improve production efficiency.

1. YTJHW2P-40 Technical Parameters

|

Item |

Details |

||||||

|

Device Name |

Fully Automatic Bar Shearing And Bending Workstation |

||||||

|

Model |

YTJHW2P-40 |

||||||

|

Raw material category |

Rods |

||||||

|

Raw material specifications |

Φ16mm-Φ40mm |

||||||

|

Conveying speed |

2.5m/s |

||||||

|

Shear force |

2500KN |

||||||

|

Blade width |

600mm |

||||||

|

Minimum cutting length |

1500mm |

||||||

|

Cut Data |

Φ16 |

Φ20 |

Φ25 |

Φ28 |

Φ32 |

Φ36 |

Φ40 |

|

30root |

25root |

20root |

18root |

15root |

10root |

8root |

|

|

Gantry speed |

X-axis direction2.2m/s Y-axis direction2.2m/s Z-axis direction0.925m/s |

||||||

|

The shortest unfolded length of the bending workpiece |

2000mm The length of one side of the curved figure needs to be greater than 1700mm |

||||||

|

Bending data |

Φ16 |

Φ20 |

Φ25 |

Φ28 |

Φ32 |

Φ36 |

Φ40 |

|

4 root |

4 root |

3 root |

2 root |

1 root |

1 root |

1 root |

|

|

Air source pressure |

0.6MPa |

||||||

|

Voltage/Frequency |

380V/50HZ |

||||||

|

Equipment power |

175.8KW |

||||||

|

Equipment weight |

52000KG |

||||||

|

Dimensions |

33600mmx10500mmx3500mm |

||||||

2.Production output

Shearing output (batch processing capacity)

|

Number |

Rebar diameter |

Cutting length |

Output per hour |

10-hour output

|

|

1. |

Φ16 |

6000mm |

18900KG |

189000KG |

|

2. |

Φ20 |

6000mm |

22000KG |

220000KG |

|

3. |

Φ25 |

6000mm |

27000KG |

270000KG |

|

4. |

Φ28 |

6000mm |

31000KG |

310000KG |

|

5. |

Φ32 |

6000mm |

33000KG |

330000KG |

|

6. |

Φ36 |

6000mm |

28000KG |

280000KG |

|

7. |

Φ40 |

6000mm |

28000KG |

280000KG |

3.Bending processing output (batch processing capacity)

|

Number |

Rebar diameter |

Curved Shape |

Workpiece unfolded length |

Output per hour |

10-hour output

|

|

|

1. |

Φ16 |

|

6000mm |

4500KG |

45000KG |

|

|

2. |

Φ20 |

6000mm |

7000KG |

70000KG |

||

|

3. |

Φ25 |

6000mm |

8200KG |

82000KG |

||

|

4. |

Φ28 |

6000mm |

6900KG |

69000KG |

||

|

5. |

Φ32 |

6000mm |

4400KG |

44000KG |

||

|

6. |

Φ36 |

6000mm |

5600KG |

56000KG |

||

|

7. |

Φ40 |

6000mm |

7200KG |

72000KG |

||

Technical advantages

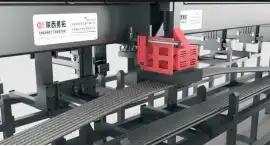

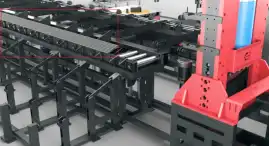

Magnetic automatic feeding:

Use magnetic suction to automatically feed steel bar raw materials, reduce manual labor intensity, safe and efficient.

Scanning and counting: Laser scanning is used to realize the feeding quantity of steel bar raw materials, which is convenient for counting the processing quantity.

Feeding trough:

The feeding trough width is 600mm and can convey multiple steel bars for processing.

Length:

The servo motor is used to drive the length movement, and the length accuracy can reach ±1mm.

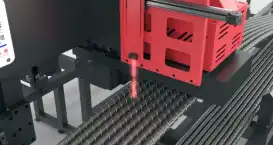

Shear head:

Adopts 2500KN hydraulic shear, heavy-duty frame design with strong rigidity, stable operation and 24-hour uninterrupted operation.

Tailing collection:

A tailing collection device is designed to collect the remaining tailings after cutting, without manual picking, which is convenient and safe.

Cutting and blanking: It can be used for cutting and blanking alone, or for cutting and bending at the same time. The dual function is more flexible.

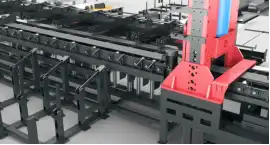

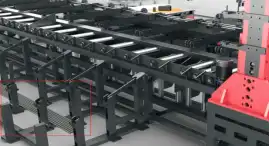

Rebar translation: The cut rebar is moved to the bending storage trough through the translation device.

Bending pre-storage trough: The steel bars of the translation device are turned into the vertical storage trough through the turning device, and the storage quantity can be set.

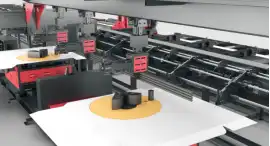

Steel bar bending and feeding:

Three sets of manipulators are used to pick up the steel bars in the storage tank and put them into the bending mold.

Steel bar bending:

Adopting high-power servo motor to drive bending, with high bending accuracy and strong power, it can process φ40mm threaded steel bars for a long time.

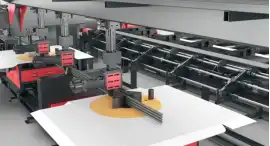

Finished product collection:

Three sets of manipulators are used to pick up the bent steel bars and place them on the receiving platform. The placement of the receiving platform can be flexibly set to meet the storage of different specifications.

YOU MAY LIKE

_1744680888628.png)