Rebar processing category: bar rebar

Processing category: cut to length

Technical advantages

① High-quality feeding, sizing, shearing and collection of bars and steel bars.

② Servo-controlled sizing, high feeding accuracy and good consistency.

③250-ton shearing cylinder, high production efficiency.

④ Equipped with tail material collection box, centralized collection of tail materials.

⑤ Double-sided six-station finished product collection bin meets the centralized collection of various specifications.

⑥The collection bin is equipped with a collection steel chain to reduce collection noise.

⑦ Optional automatic raw material feeding device to reduce the intensity of feeding work .

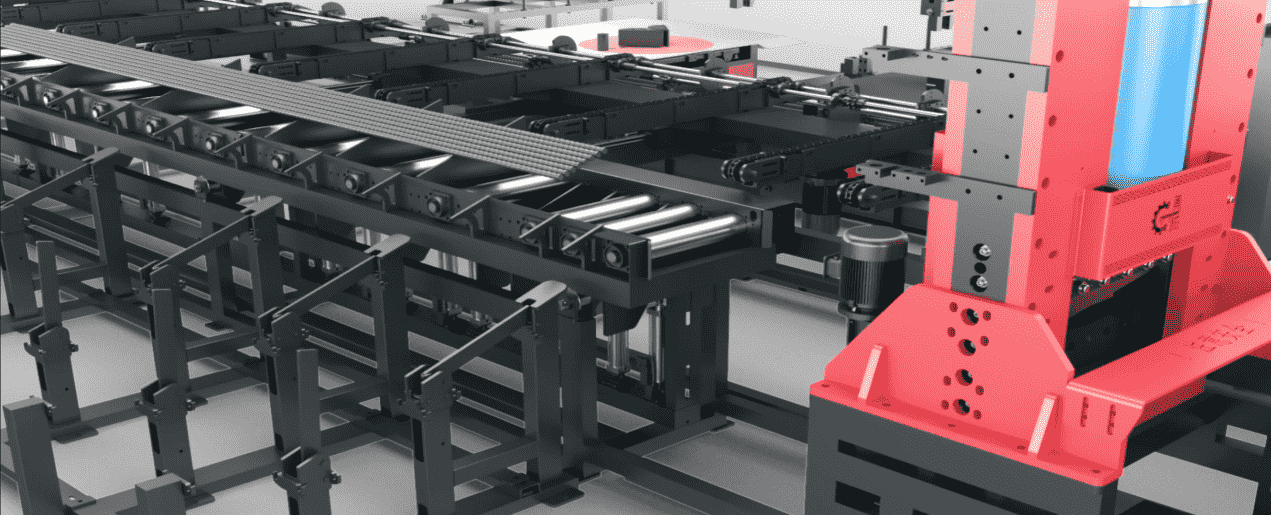

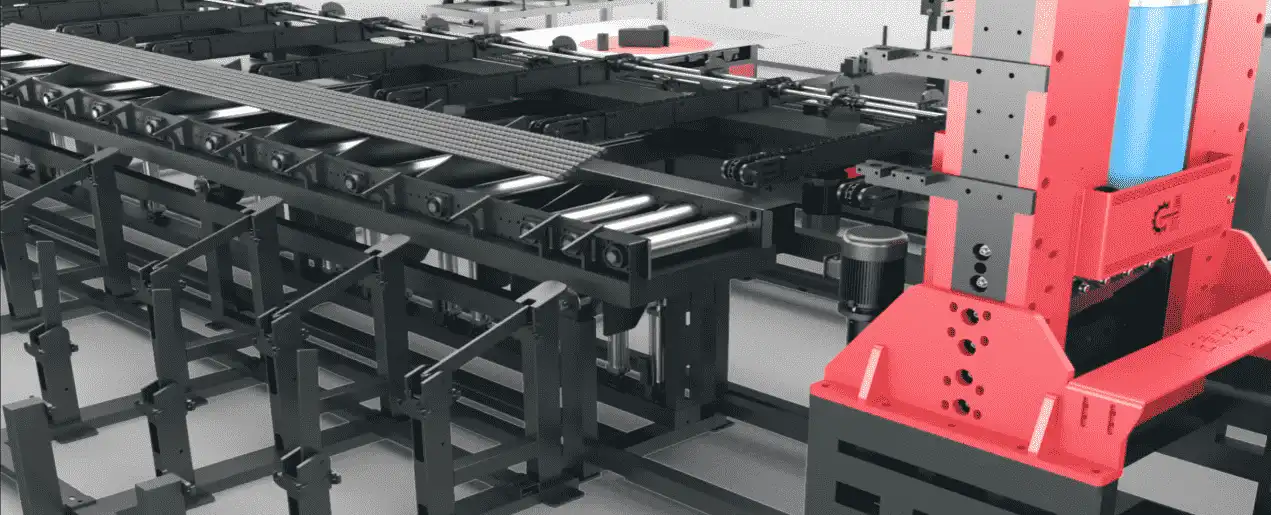

Ⅰ、YTQ-600 CNC steel bar shearing production line

Rebar processing category: bar rebar

Processing category: cut to length

Ⅱ、Technical advantages

① High-quality feeding, sizing, shearing and collection of bars and steel bars.

② Servo-controlled sizing, high feeding accuracy and good consistency.

③250-ton shearing cylinder, high production efficiency.

④ Equipped with tail material collection box, centralized collection of tail materials.

⑤ Double-sided six-station finished product collection bin meets the centralized collection of various specifications.

⑥The collection bin is equipped with a collection steel chain to reduce collection noise.

⑦ Optional automatic raw material feeding device to reduce the intensity of feeding work .

Ⅲ、Technical parameters

|

Model |

YTQ600 |

Rebar processing diameter |

Φ12-φ40mm |

||||

|

Blade width |

600mm |

Shear force |

2500KN |

||||

|

Conveying speed |

2.5m/s |

Shear frequency |

22time/min |

||||

|

Cutting length |

1500-12000mm |

Air source pressure |

0.6MPa |

||||

|

Voltage/Frequency |

380V/50HZ |

Machine power |

66KW |

||||

|

Machine weight |

22000KG |

Host size |

28000x7000x2500mm |

||||

|

Cut Data |

Φ16 |

Φ20 |

Φ25 |

Φ28 |

Φ32 |

Φ36 |

Φ40 |

|

30 roots |

25 roots |

20 roots |

18 roots |

15 roots |

10 roots |

8 roots |

|

Ⅳ、Production output

Shearing output (batch processing capacity)

|

Number |

Steel bar diameter |

Cutting length |

Hourly output |

10 hours output |

|

1. |

Φ16 |

6000mm |

18900KG |

189000KG |

|

2. |

Φ20 |

6000mm |

22000KG |

220000KG |

|

3. |

Φ25 |

6000mm |

27000KG |

270000KG |

|

4. |

Φ28 |

6000mm |

31000KG |

310000KG |

|

5. |

Φ32 |

6000mm |

33000KG |

330000KG |

|

6. |

Φ36 |

6000mm |

28000KG |

280000KG |

|

7. |

Φ40 |

6000mm |

28000KG |

280000KG |

1.Feeding trough:

2. The feeding trough is 600mm wide and can transport multiple steel bars for processing

3. The feeding roller is quenched and has a long service life

4. Length setting: Servo motor is used to drive the length setting, and the length setting accuracy can reach ±1mm

5. Shear head: 2500KN hydraulic shear, heavy-duty frame design, strong rigidity, stable operation and 24-hour uninterrupted work

6.Tailings collection: A tailings collection device is designed to collect the remaining tailings after shearing. No need to pick them up manually, which is convenient and safe.

Cutting and unloading: Double-sided six-station material collection bin, which can collect finished steel bars of various specifications

Ⅳ、Standard configuration list of YTQ-600 CNC steel bar shearing production line

|

Number |

Denomination |

Specification |

Quantity |

Remark |

|

1 |

Host |

YTQ600 |

1 set |

|

|

2 |

Air Compressor |

Equipment supporting special |

1 set |

7.5KW |

|

3 |

Random accessories, tools and operating manual |

Equipment supporting special |

1 set |

YOU MAY LIKE

_1744680888628.png)