① The steel bar feeding is operated by a wireless remote control, which is convenient and quick to use

② The arc straightening mechanism can effectively control the axial torsion of the steel bar, and the overlap of the processed parts is flat. In addition, the arc feeding increases the contact surface between the steel bar and the feeding wheel, reducing the damage to the surface tissue of the steel bar

③ The double-line independent clamping feeding mechanism can ensure the consistency of the length of the two steel bars processed by the double line

④ Servo control wire feeding and bending, high precision of feeding length and bending angle

⑤ Wire feeding, bending, using planetary reducer as torque transmission, high torque transmission efficiency, high precision, long service life

⑥ The electrical cabinet is installed with industrial air conditioning, the internal temperature of the electrical box is constant, to ensure that the equipment runs at the highest performance

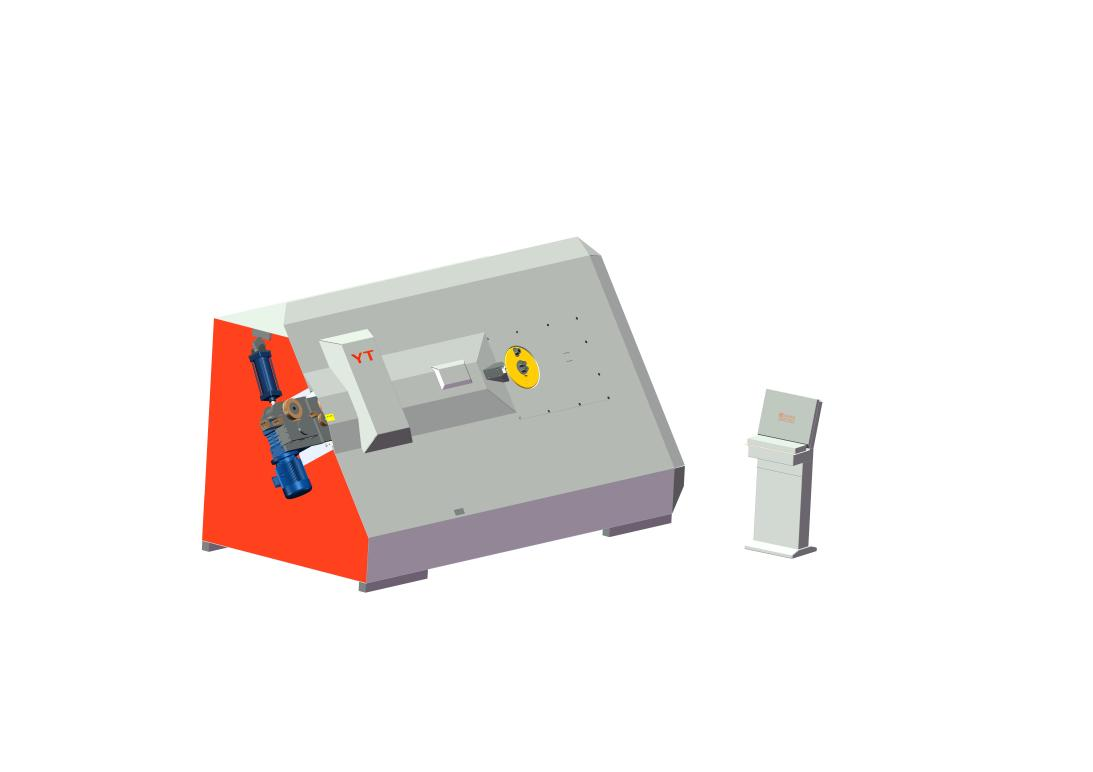

一、YT-16 Bidirectional fully automatic CNC hoop bending machine technical advantages, parameters and dimensions

1. Technical parameters

|

Model |

YT-16 |

Rebar processing diameter |

Φ8mm-Φ16mm |

|

Bending direction |

Bidirectional |

Processing Capabilities |

Double LineΦ8mm-Φ14mm |

|

Single LineΦ8mm-Φ16mm |

|||

|

Bending Angle |

1-180° |

Bending speed |

600°/S |

|

Voltage/Frequency |

380V/50HZ |

Maximum traction speed |

170m/min |

|

power |

68.4KW |

Air source pressure |

0.6MPa |

|

Host weight |

4000KG |

Host size |

4890mmx1900mmx2250mm |

2.Technical advantages

① The steel bar feeding is operated by a wireless remote control, which is convenient and quick to use

② The arc straightening mechanism can effectively control the axial torsion of the steel bar, and the overlap of the processed parts is flat. In addition, the arc feeding increases the contact surface between the steel bar and the feeding wheel, reducing the damage to the surface tissue of the steel bar

③ The double-line independent clamping feeding mechanism can ensure the consistency of the length of the two steel bars processed by the double line

④ Servo control wire feeding and bending, high precision of feeding length and bending angle

⑤ Wire feeding, bending, using planetary reducer as torque transmission, high torque transmission efficiency, high precision, long service life

⑥ The electrical cabinet is installed with industrial air conditioning, the internal temperature of the electrical box is constant, to ensure that the equipment runs at the highest performance

二、 YT-16 Bidirectional Fully Automatic CNC Hoop Bending Machine Standard Configuration List

|

Number |

Denomination |

Quantity |

Remark |

|

1 |

Host |

1 set |

|

|

2 |

Feeding cage |

1 set |

set/2 PCS |

|

3 |

Air Compressor |

1 set |

7.5KW |

|

4 |

Random accessories, tools and operating manual |

1 set |

YOU MAY LIKE

_1744680888628.png)